Editor's word: do the machinery industry, especially people doing machining, had to be very familiar with a variety of fixtures, so today I first give you ten of our commonly used fixtures, you know a few of them?

Tenth place: indexing head

Once a great success, now it's gone. It's all the fault of the index spindle. So you'll have to settle for 10th.

Ninth place: Pneumatic cylinder jig

The essence of automatic clamping fixtures. Of the many jigs available the labourer should like the pneumatic jig the best.

Eighth place: Spring collet/clamp

How do you solve the clamping problem with a wide range of tool sizes with fewer tool handles? Here you can find the answer.

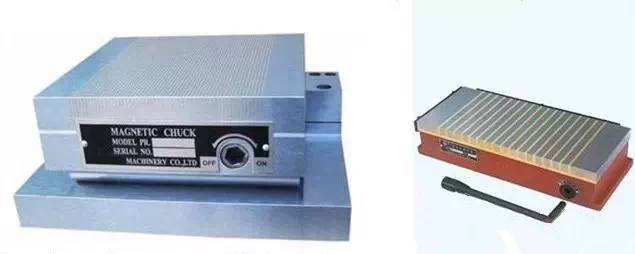

Seventh place: Magnetic stage

How can you make it even easier to put parts without a clamping position on the table for you to machine? See how he does it?

Sixth place: spindle and toolholder

The spindle and shank are the result of top human ingenuity and cutting-edge technology.

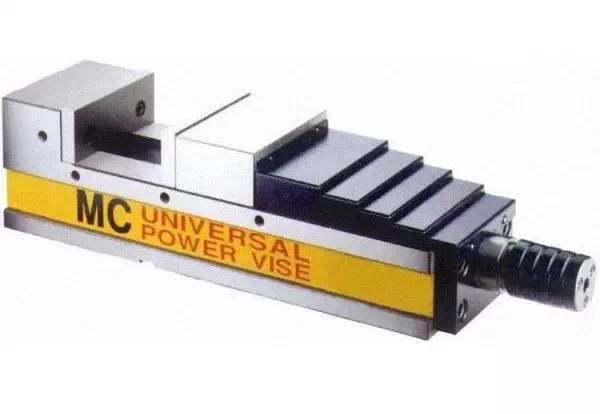

Fifth place: the vise; and his brother Maxi

Workpieces that cannot be pressed by the platen will have to be considered for vise/mesh clamping.

Fourth place: EROWA clamps

It guarantees a repeatable positioning accuracy of /-0.002 mm. Electrodes don't work without it; four-axis machining doesn't work without it; five-axis machining doesn't work without it.

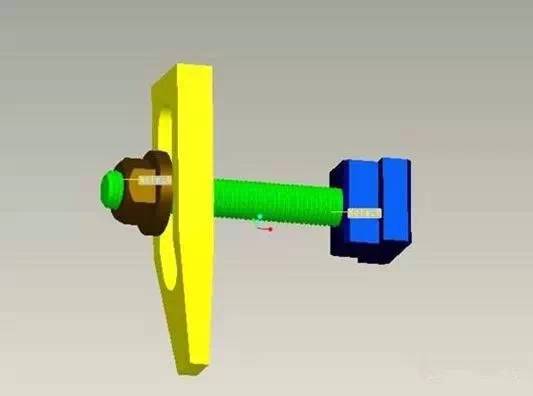

Third place: combination of T-block, screw, platen and nut

You can't make any other fixtures without a combination of T-blocks, screws, platens and nuts you can hardly fit to the machine (for milling machines, machining centres). If you don't believe me, try it.

Second place: T-table

Don't look at his usual inconspicuous, if another day you find your machine tool without a T-table you will certainly be at a loss.

Number one: the chuck

The 100 year old jig is still busy in the machine shop. Its classicism speaks for itself. There are more chucks in the workshop than lathes. Without chucks the lathe would not be able to operate.