With the rapid development of the automobile industry, the efficient, high-precision and stable processing of the complex main parts of the automobile is an effective way to shorten the product production cycle and improve the efficiency and competitiveness of enterprises. CNC machining technology makes rapid prototyping and manufacturing of complex automobile parts possible.

At the same time, virtual manufacturing technology, flexible production technology and CNC integrated manufacturing technology are widely used in modern automobile processing and manufacturing. The intelligent development of NC manufacturing technology in the process of automobile parts manufacturing will become the development trend of automobile manufacturing industry.

CNC machining technology can realize rapid prototyping and manufacturing of complex automobile parts. Virtual manufacturing technology, flexible production technology and CNC technology integrated manufacturing technology are gradually being applied in modern automobiles. It is widely used in the manufacturing industry. The intelligent development of CNC system in the process of automobile parts manufacturing will also become the inevitable trend of modern automobile manufacturing industry. Automobile industry.

The Importance of CNC Machining parts in Auto Parts Manufacturing

Compared with manual processing, CNC processing technology has realized the standardization and standardization of automobile parts manufacturing, laying a foundation for improving the production quality and operating rate of domestic automobile parts.

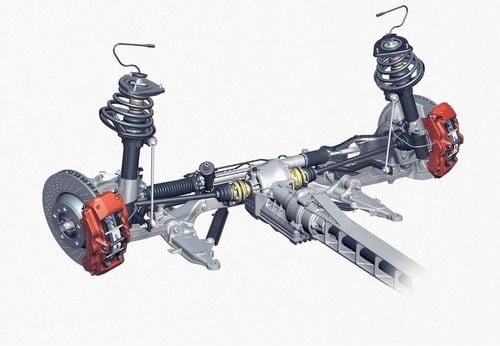

CNC technology can provide a complete set of automation solutions for the manufacturing of major auto parts. In the process of processing, it receives processing data based on industrial Internet and big data monitoring and remote service, carries out virtual processing and program code inspection, uses the processing status of the CNC system to carry out automatic identification, self-learning and adaptive functions, and self optimization functions to achieve high-quality processing of workpieces, uses industrial robots and CNC machine tools to conduct online batch testing, and implements efficient and flexible processing of major automobiles and CNC in batch manufacturing, Realize the wide application of machine tool parts.

Status quo of CNC customized processing in automobile industry

Some companies, such as Porsche, have turned to customized CNC processing to produce equipment for rare and limited vehicles or vehicles that owners or stores may not be able to use.

Traditionally, if one of the 52000 different parts that make up the Porsche classic model catalogue is out of stock in the warehouse, specific tools are needed to make more parts. Customized CNC machining is not applicable. This process is more cost-effective than building a factory to produce specific parts, and each part can be ordered within hours or days, reducing the amount of warehouse space required.

Porsche tested this movement by CNC machining and customizing the Porsche 959's fully functional clutch release lever. The lever must pass the same tests as the original machined part, including a 3 ton pressure test. As part of the pilot program, the manufacturer plans to add 20 parts to its digital library and expand as needed.

Custom car design is limited to ordinary car owners. The driver can choose interior and exterior colors and accessories, but the make, model and appearance of the vehicle are the same as any other specific model on the road. Rolls Royce is committed to creating fully customized vehicles for buyers with large budgets using CNC processing and customization.

This customization technique for CNC machining is not technical. In fact, 30% to 40% of the new Rolls Royce drivers will choose the stock models from the dealers instead of ordering their own customized models. Provides you with the option to create a custom vehicle that allows you to design everything from the frame and body to the interior entertainment console. This could expand the luxury car industry in ways that manufacturers never expected.

Prospect of the development trend of cnc system in the future

In the face of the demand of high quality, high efficiency and integrated intelligent manufacturing of multi degree of freedom complex parts, the future CNC system will develop towards multi degree of freedom compound machining. Turning, milling and drilling can be completed on multiple surfaces in one installation. Multi process compound processing. In addition, the CNC system must have more advanced trajectory planning and motor control strategies to achieve high-speed and high-precision machining.

With the development trend of intelligent manufacturing, CNC system must be equipped with highly intelligent human-machine interface to realize the planning function of machining process and the diagnosis and adaptive control strategy of machining process.

The future CNC system will provide comprehensive self-monitoring and control in the whole machine tool manufacturing process. The CNC system can automatically plan the installation position, machining path and machine tool according to the 3D model of the part. Planning time is the shortest process step, and Ethernet and Internet technologies may be used to achieve machine communication and collaboration in the factory. Manipulator communication realizes automatic loading and unloading, loading and unloading, and automatic and intelligent rapid prototyping and manufacturing of major complex parts.