With the development and progress of modern science and technology, the basic medical level has long been unable to meet people's needs, and high-end medical care has gradually entered the public's sight. The future medical industry will be deeply integrated with digital technology and smart medicine.

According to relevant industry analysis reports, the world may tend to develop telemedicine. The United States may prefer to use equipment/APP to share health information and remote technology; On site (synchronous) video consultation and remote diagnosis will become the future trend in Europe, Japan will also develop medical equipment Internet,China tends to provide for the elderly with wisdom and health.

High end medical technology can not be separated from advanced medical equipment precision processing parts. As the country pays more attention to the development of the medical industry, the scale of the medical equipment market is also increasing year by year. The development of the medical device industry has driven the market of upstream transmission parts. Among many transmission parts, precision machining parts for medical devices are the most common. Don't underestimate this seemingly ordinary gear, but it is the "joint" of various medical devices.

For medical devices, high-precision gears are indispensable to play a role. Like the common medical lifting mobile bed in the hospital, it can move freely with the help of small module gear transmission; Some minor operations that cannot be completed by human power need to be completed by surgical robots, which are precisely driven by high-precision gears. Therefore, in the medical device industry, high-precision gears are indispensable.

Application of precision machining parts of medical devices in medical injection pumps:

In some clinical situations, accurate dosage is required, especially for some severe patients, no matter how much or how little dosage is, it will have an impact on patients. However, there is a gap in the control of drugs by ordinary medical personnel, so a product that can accurately control the dosage and speed is needed.

The medical injection pump is such a product, which can accurately control the quantity and flow rate of infusion, and improve the efficiency and flexibility of clinical drug delivery operation. Under the premise of strict control of drugs, the medical injection pump needs to use high-precision transmission components, and high-precision gear is an indispensable transmission part in the injection pump.

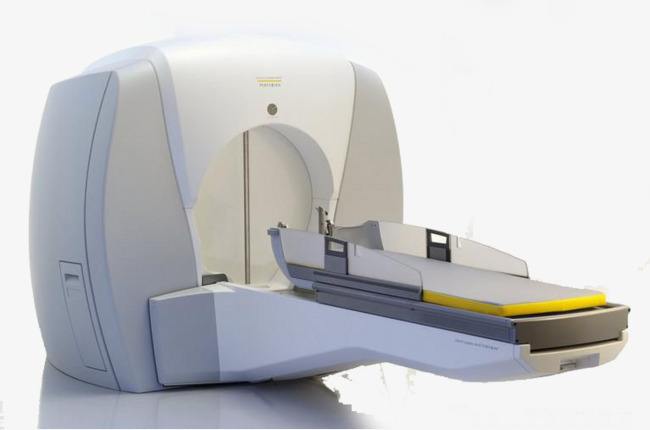

Application of precision machining parts of medical devices in robotic surgery:

At present, a difficult operation often takes a long time. In a long standing operation, the human status will inevitably decline. Through robotic surgery, the robot arm can simulate all kinds of human hand operations 360 ° without blind spots, and has a humanoid hand joint, and the operation accuracy is even higher than that of human hand operations. In extrathoracic surgery, this kind of mechanical arm beyond the ability of human hands can help doctors reduce the difficulty of operation in narrow space, so as to reduce injuries, reduce intraoperative bleeding and improve the incidence of postoperative complications.

The gears used in high-end medical equipment have special requirements for precision and process, especially for the strict control of precision machining parts of medical devices. Advanced equipment and processing technology are needed to produce products that meet the requirements. In 24 years of gear production experience, iHF Hefa Gear has more than 300 sets of precision gear production equipment and advanced testing equipment, which can be customized according to customer needs. It has provided medical equipment special gears for Mindray Medical and other enterprises for a long time.