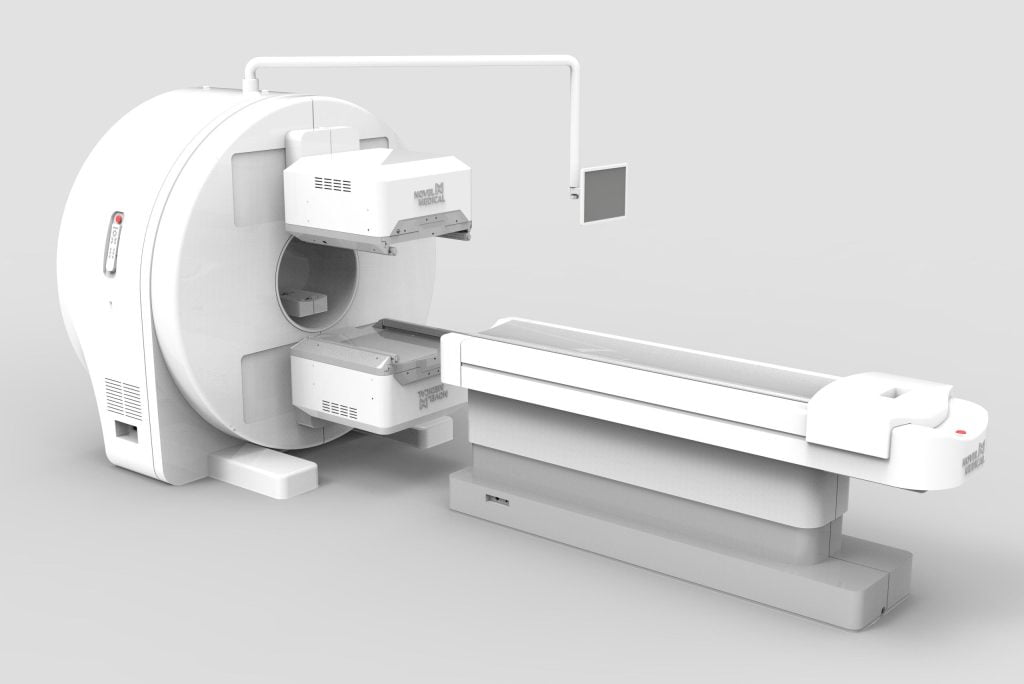

In the post epidemic era, the public's health awareness has been continuously enhanced, which has promoted the rise of the medical and health industry, which runs counter to the rapid growth trend of the global demand for medical devices. According to the medical technology assessment, the global market volume of medical devices will reach 451.9 billion dollars in 2019. It is estimated that by 2024, the global market capacity of medical devices will be close to US $600 billion. The global market has full development potential.

The accelerated development of the global market will certainly link its upstream and downstream industrial chains, bring huge demand for medical equipment processing, and bring a new wave of development to the precision parts manufacturing market.

Precision machining - reduce cost and improve the efficiency and precision of precision machined parts of medical devices.

Medical equipment is famous for its complex structure, high precision and reliability requirements. The higher requirements for workpiece materials, machining accuracy, surface finish and other aspects of medical device parts also mean that precision machined parts of medical devices.

In the field of medical precision machining, turning milling composite machining technology and micro machining technology are commonly used. Facing higher processing requirements in the future, how can these two technologies occupy the medical precision processing field?

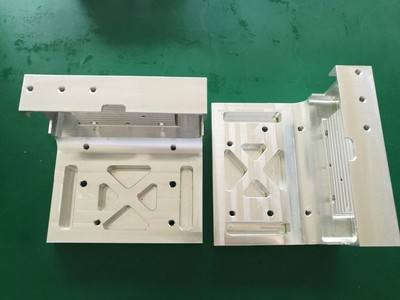

The turning milling compound machining center can realize the machining of multiple or complex surfaces of parts through one clamping, greatly simplifying the complexity of workpiece clamping and tool system, and reducing clamping and non production time.

In addition, the turning milling compound machining center can adopt high-speed milling and high-speed cutting, with large cutting volume, to meet the needs of users in improving production efficiency, ensuring machining accuracy, reducing parts transmission and inventory, and reducing floor space.

In addition, in medical devices, there are many very small and precise parts, such as blood dialyzer parts, filters, small bone nails, etc., and micro processing technology has more advantages in this regard.

Compared with EDM and laser processing, micro drilling will not burden the workpiece, and can achieve high-precision, clean internal surface opening of precision machined parts of medical devices.