CNC Turning and Milling Services

V1 Machining as a offers CNC Turning and Milling service of company has cooperated with many companies in the United States, Germany, and Canada for up to 10 years. Fast DMF assessment, efficient service, is the beginning of our cooperation.

- Tolerances up to +-0.001mm.

- Prototypes can be processed in as little as 1 day.

- Tolerances up to +-0.001mm.

Prototypes can be processed in as little as 1 day. - High quality management system including ISO 9001:2015, ISO 14001:2015, IATF 16949 certification to ensure high level and high precision parts.

What is CNC Turn-Milling Compound?

CNC turning or CNC milling allows to manufacture CNC parts in single handling, while CNC milling-turning is a compound machining technology, to execute designed multiple kinds of tasks with the computer numerical control when the cutting tool and workpiece are both rotating. With CNC milling and turning services, complex curved or special-shaped parts can be produced through the processing of multiple surfaces on the CNC milling-turning center. CNC turn-milling machine can reach any surface of the components. Most of the CNC turn-milling compound process can be completed on the CNC turning center. There are two different CNC turning-milling types:

– Contour machining when the workpiece is parallel to the cutter axis

– Surface machining when the workpiece is vertical to the cutter axis.

Rapid CNC Turning and Milling Services

V1 Machining is a leading CNC manufacturing company in China, providing efficient and quick CNC milling and turning services for precision machined components manufacturing and prototyping. We have sophisticated high-performance multi-axis CNC milling-turning center, accomplished workers and operators to provide quality custom CNC turn-mill parts with improved productivity and outstanding flexibility. Our CNC design and engineering team will review your drawings carefully and rigorously, then give you proper advice or start the machining cycle. You can get detailed CNC mill-turning quote fast as long as you sent your metal or plastic parts design drawings. Highly automated CNC programming will speed up and simplify the machining of CNC milling and turning components and achieve tight tolerance, smooth surface and complex geometries to meet your requirements.

Advantages of V1 CNC Turning and Milling

High efficiency

We can produce 1-1000 CNC milling and turning parts as fast as one day with our equipment.

Excellent Precision

Based on customer demands, Jun Ying will provide precise and accurate measurement and production for each product.

Exact Specifications

Automatic CNC milling-turning center will perform the designed motions to get required parts with exact sizes, shapes and other parameters.

Competitive Prices

With advanced CNC machining services and increased productivity, we can bring you the most cost-effective and affordable custom solutions.

Quality Guaranteed

Carefully picked raw materials and strict quality control system throughout the whole project, ISO9001:2015 certification.

Fast Delivery

Average 7 days turnaround time and 99.85 on-time delivery rate.

Products

.01

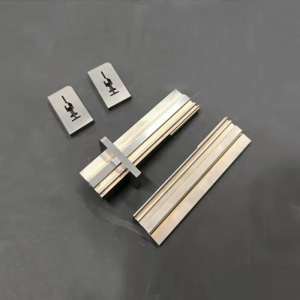

Mechanical Parts Machining's Capacity

For processing orders of mechanical part, all are produced and processed by “Mechanical Parts Machining Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

72

Production equipments

49

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

.02

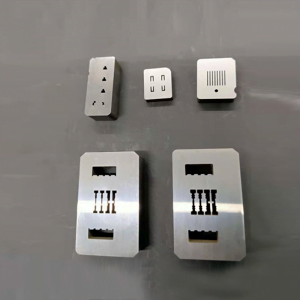

Precision Mold Parts Machining's Capacity

For processing orders of precision mold parts, all are produced and processed by “Precision Mould Parts Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

66

Production equipments

24

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

.03

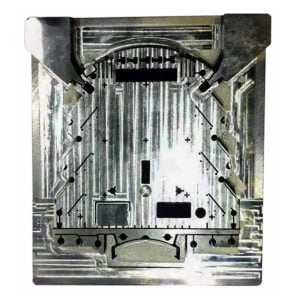

Large Parts Machining's Capacity

For the processing and customized orders of Large parts, the “Large CNC Machining Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

59

Production equipments

154

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

CNC Manufacturing Materials

Choose the right materials for your manufacturing needs from prototype to production

Applications Industries of Parts CNC Machining

V1 machining is a CNC company offering services suitable for mass production of high-precision mould parts, large Die parts and various mechanical parts, such as components for cell phones, medical devices, optical equipment, automobile, the lighting industry, office equipment, etc. We know that CNC machining has become the most basic, extensive and important technology in the mechanical manufacturing industry, which directly affects production efficiency, cost, energy consumption, and environmental protection. The CNC machining applications involves the following industries:

Custom CNC Turning and Milling Services

If you need any metal and plastic materials cnc Turning and Milling and custom surface treatment services