The concepts of component interchangeability and dimensional tolerances have become an accepted part of the manufacturing industry. Unfortunately, the misuse of the latter can lead to a number of problems. For example, overly tight tolerances may require parts to be ground or EDM'd twice to complete, unnecessarily increasing costs and lead times. Tolerances that are "too loose" or do not match the tolerances of the mating part may make assembly impossible, leading to the need for rework or, at worst, rendering the finished product unusable.

To avoid these unpleasant situations, this design tip includes some guidance on how to apply part tolerances correctly, as well as definitions of some of the more commonly used markings. We will also look at the industry standard for part tolerances, called Geometric Dimensioning and Tolerancing (GD&T).

- Standardised tolerances for CNC machining

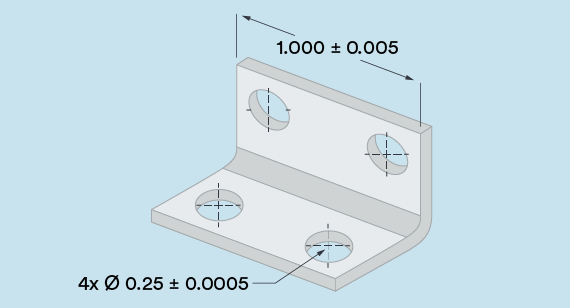

Standard prototype and production machining tolerances of +/-0.005" (0.13mm) are assumed. This means that the position, width, length, thickness or diameter of any part feature will not deviate from the nominal value by more than this value. If you plan to machine a 1" (25.4 mm) wide bracket, the dimensions will be between 0.995 and 1.005" (25.273 and 25.527 mm) and the bracket has a 0.25" (6.35 mm) hole in one leg, the diameter of the bracket will be 0.245 to 0.255" (6.223 to 6.477 mm) as shown below.

This is very close, but if you require higher accuracy, which needs to be judged by the geometry and material of the part, please ensure that this is stated in the part design when uploading the file for quotation.

- CNC Machining Tolerance Guide

Also, please note that these are bilateral tolerances. If expressed in single-sided terms, the standard tolerance should be +0.000/-0.010 in. (or +0.010/-0.000 in.). All of these are acceptable, as are the metric values, provided you specify them in detail in your design. To avoid confusion, please observe the "three dimensional" dimensions and tolerances shown and avoid the additional zero position of 1.0000 or 0.2500 in. Unless there is an absolute reason to do so. 3.

- Surface roughness considerations for machining tolerances

In addition to length, width and hole dimensions, there are part tolerances such as surface roughness. For standard products, surface roughness for flat and vertical surfaces is equal to 63µin. while curved surfaces are better equal to 125µin.

For most purposes this is a sufficient finish, but for decorative surfaces on metal parts we are often able to improve the appearance by light sandblasting. If you require a smoother surface, please specify this in your design and we will do our best to meet your requirements.

- Geometric dimensions and tolerances

There is one more consideration. As mentioned earlier, we can accept GD&T tolerances. This provides a deeper level of quality control, including the relationship between various part features and shape and fit qualifiers. The following are some of the more common methods.

True position: In the bracketed example quoted earlier, we marked the hole position by specifying the X and Y distances and their allowable deviation from a pair of vertical part edges. In GD&T, the position of the hole will be indicated by the true position of a set of reference datums with the qualifiers MMC (maximum material condition) or LMC (minimum material condition).

Flatness: Milled surfaces are usually very flat, but due to internal material stresses or clamping forces during machining, some warping may occur after the part is removed from the machine, especially for thin-walled and plastic parts.GD&T flatness tolerances control this by defining two parallel planes in which the milled surface must lie.

Cylindricity: for the same reason most milled surfaces are very flat and most holes are very round, as are turned surfaces. However, using a tolerance of +/-0.005" (0.127 mm), the 0.25" (6.35 mm) hole in the bracket example may be rectangular, with another one-way dimension of 0.245" (6.223 mm) and 0.255" (6.477 mm). Using a cylindricity defined as two concentric cylinders in which the machined hole must lie, the manufacturer can eliminate this unlikely situation.

Concentricity: the rings in the bullseye are concentric, just as the wheels on a car are concentric with the axle. If a drilled or reamed hole must be perfectly aligned with a coaxial countersunk hole or circular boss, concentricity marking is the best way to ensure this.

Perpendicularity: As the name implies, perpendicularity determines the maximum deviation of a horizontally machined surface from a nearby vertical surface. It can also be used to control the perpendicularity of a turned shoulder to an adjacent diameter or to the central axis of the part.

So, what is the difference between our machining options? Firstly, quotations for high precision/high quantity machining are not as automated as our automated machining options, so quotations may need to be reviewed manually. With high precision machining, the lead time for delivery of the finished product is also slightly longer. We require 3D CAD models, as well as 2D drawings for GD&T tolerances. This may also mean that we go beyond our standard cutting tool set and use machining processes such as wire cutting, EDM drilling, grinding and boring to meet your part quality requirements.

In addition, V1machining is certified to the ISO 9001 quality system and, on request, we will carry out 100% full inspection of your parts, as well as providing quality inspection reports, first article inspection (FAI), material certification, etc. If you have a part to be machined, contact us via the V1machining website and we will provide you with a quotation and arrange for a professional pre-sales engineer to assist you.