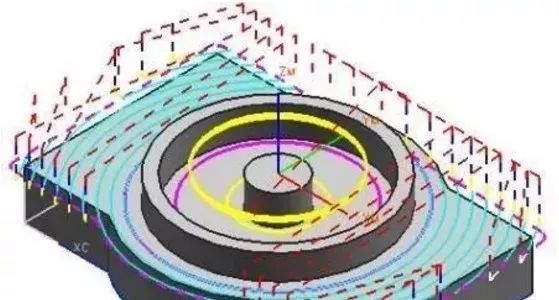

- Reciprocating cutting.

The reciprocating cutting method creates a reciprocating parallel cutting tool track that maintains continuous motion during the step motion, without lifting the tool to maximise removal of the material, and is the most economical and trouble-free cutting motion. This method of cutting paralleling and counter-attacking co-exist, and if operational wall clearance is enabled, the direction of the tool track for wall clearance is affected to maintain wall clearance as purely paralleling or counter-milling.

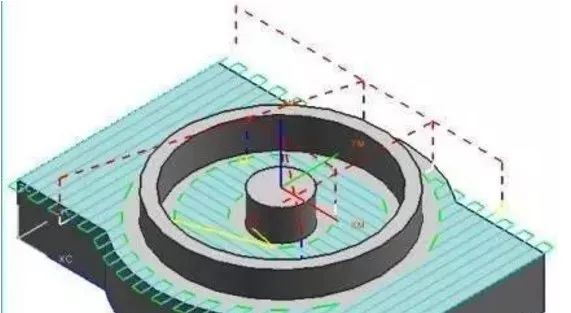

- One-way cutting.

The unidirectional cutting method produces a parallel and unidirectional cutting toolpath, the return stroke is a rapid traversing movement, as no cutting is produced on the return stroke, so machining efficiency is affected. Unidirectional cutting can always maintain a consistent smooth or reverse milling cutting, usually used for surface processing of islands and not applicable reciprocating cutting method of occasions, such as some steep-walled fascia, generally used with the surface finishing.

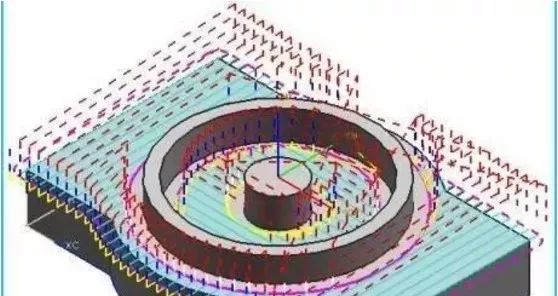

- Unidirectional cutting along the contour.

One-way cutting along the contour is used to create parallel, one-way, toolpaths along the contour, always maintaining a down-mill or counter-mill cut. The quality of the machined wall surface is better than reciprocating cutting and one-way cutting, and the cutting is smoother, no impact on the tool, so it is usually used to process parts with higher sidewall requirements or thin-walled parts.

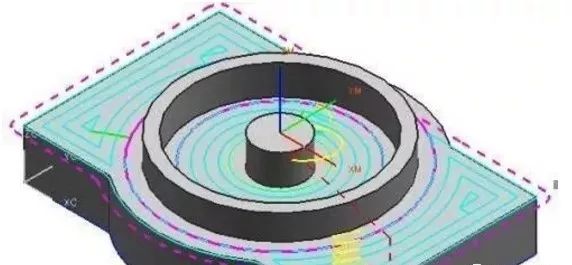

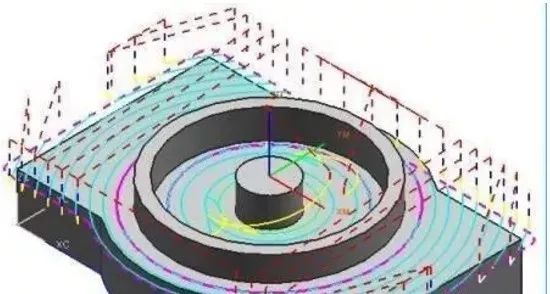

- following the periphery cutting.

Follow the periphery cutting method is mainly used to create a sequential, concentric toolpath along the contour, which is obtained by offsetting the peripheral contour, all trajectories are presented in closed form in the machining area. Following the periphery cutting toolpath is a continuous cutting toolpath with no air cuts and is basically able to maintain a purely down milling or reverse milling, thus providing both high cutting efficiency and stable cutting and quality assurance, usually for rough machining of parts with islands and internal cavities.

- Following the workpiece cutting.

Follow the workpiece cutting method produces a series of tool tracks that imitate all the specified contours of the part being machined, both the outer peripheral wall of the imitation cutting area and also the islands in the imitation cutting area, the shape of these tool tracks is obtained by offsetting the outer contours of the cutting area and the island contours. The toolpaths that follow the workpiece cutting are continuous cutting toolpaths, learn CNC programming group 726236503 help you. There is no empty cutting, can maintain purely down milling or reverse milling, so both high cutting efficiency can also maintain cutting stability and ensure the quality of machining, usually used in the cavity processing area with islands.

- Pendulum cutting.

The cycloid cutting method is used to produce a small circle around the contour, thus avoiding the occurrence of a full tool cut in cutting resulting in too much material being cut. Cycloid cutting is suitable for high speed machining, with a more uniform cutting load for processing.