3 axis, 4 axis, 5 axis CNC machining, in our industry work is often heard in the term, sounds very high, perhaps you also have some image, but how exactly is the matter, may be some users can not say.

For these types of CNC machining, it is still necessary to understand the general situation, our work will also be of great benefit.

CNC milling machines are classified by the number of axes they operate. These movements determine the characteristics of the parts that can be manufactured and can also affect productivity and precision.

Generally speaking, the more degrees of freedom available, the more complex the geometry that can be produced.

So what is the difference between 3, 4 and 5 axes? What are their respective advantages? Which products are they suitable for? Let's take a look at them together with Xiaoqi.

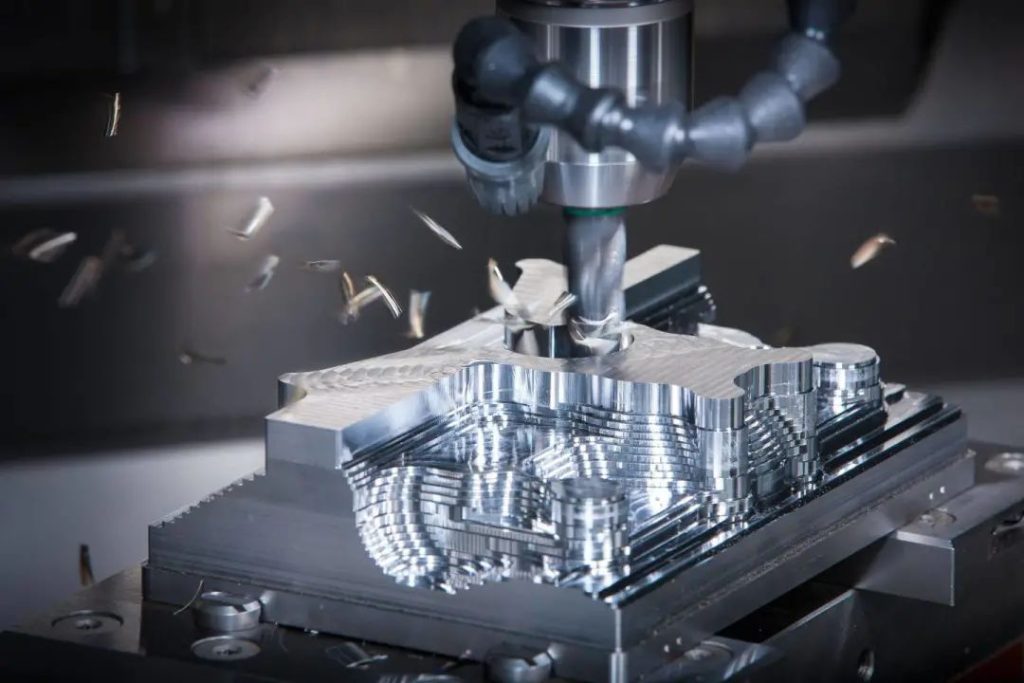

3-axis CNC machining

3-axis CNC machining generally refers to three different directions of linear movement of the axis, such as up and down, front and back, left and right.

Three axes can only process one surface at a time, suitable for processing some disc parts, for many parts that need to process holes or grooves on multiple surfaces, this is a limitation.

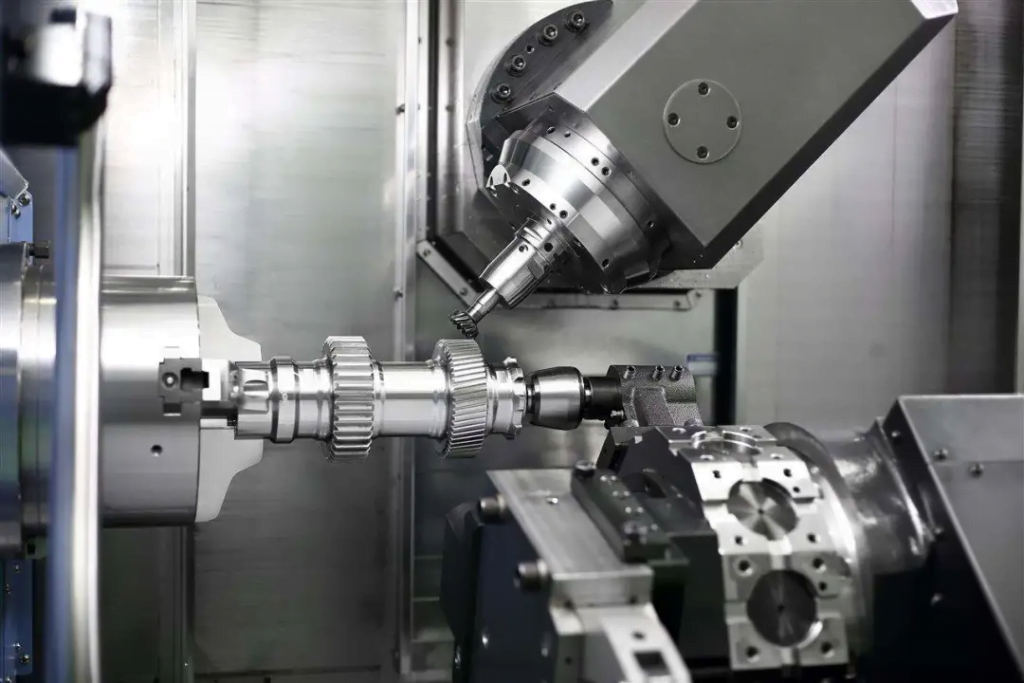

4-axis CNC machining

4-axis CNC machining is the addition of a rotary axis to the 3-axis, generally 360° rotation in the horizontal plane. However, it cannot be rotated at high speeds and is suitable for machining some box-type parts.

Most 4 axis CNC machines also allow the workpiece to rotate, this is known as the b-axis, so that the machine can act as both a milling machine and a lathe.

If you need to drill holes in the side of a piece or in the curved surface of a cylinder, 4-axis CNC machining is the way to go. It speeds up the machining process considerably and has a high degree of machining accuracy.

5-axis CNC machining

5-axis CNC machining is a rotary axis on top of the 4-axis, generally 360° rotation of the upright surface, the 5-axis can already be fully processed, can achieve a clamping, can reduce the cost of clamping, reduce product scratching and bruising.

Due to its high versatility, 5-axis CNC machining can be used to manufacture complex precision parts. Examples include medical components for artificial limbs or bones, aerospace components, titanium components, oil and gas mechanical components, military products, etc.

How to choose:

Although the advantages of 5-axis over 4-axis and 3-axis are outstanding, not all products are suitable for 5-axis machining. What is suitable for 3-axis machining is not necessarily suitable for 5-axis machining, and if products that can originally be machined with 3-axis are machined with 5-axis, not only will the cost increase, but the results are not necessarily good.