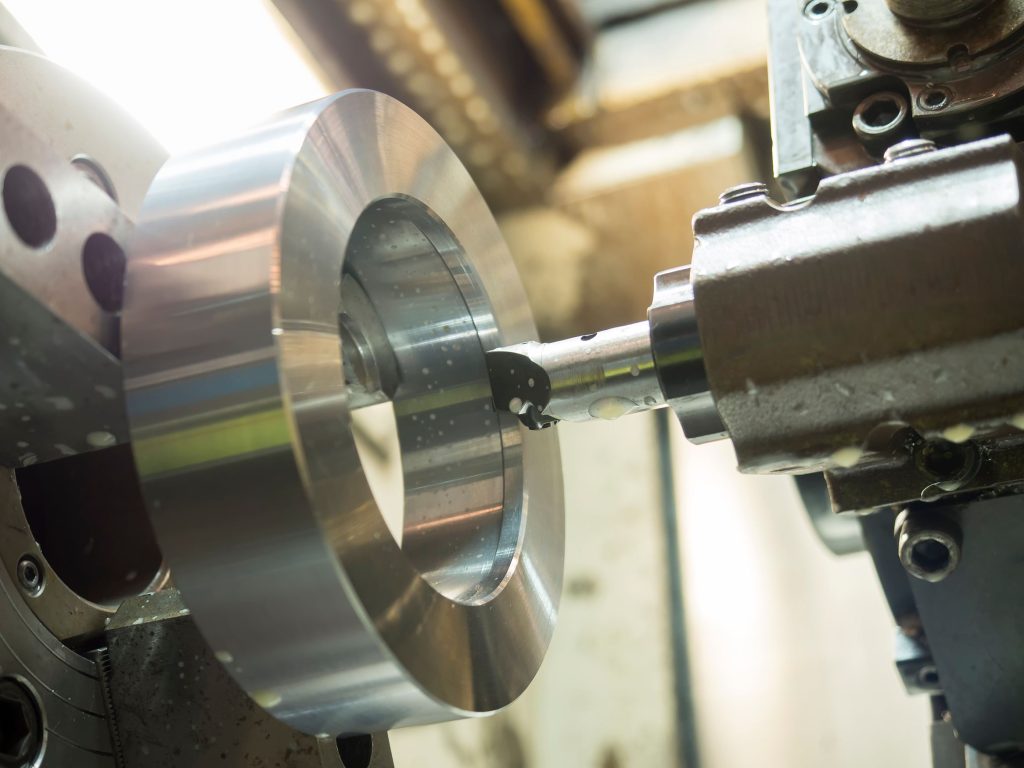

Double spindle turning and milling compound machine tool is the latest trend in the development of machine tools in the world. This compound type of processing method can make the mechanic operation of the machine become more simple, without continuous storage and handling between processes, so as to improve the accuracy of workpiece processing and shorten the processing time.

Advantage one, discontinuous cutting

The double spindle turn-milling compound machining method is a discontinuous cutting method. This discontinuous type of cutting allows the tool to have more cooling time, because no matter what kind of material is processed, the temperature reached by the tool when cutting is relatively low.

Advantage two, easy to high-speed cutting

Compared with the traditional car milling compound technology, the double spindle car milling compound machining technology is more easier for high speed cutting, and so on all the benefits of high speed cutting is able to get in double spindle car milling compound machining several, such as double spindle car milling compound cutting force is higher than traditional cutting down thirty percent.

In cutting force just can reduce the workpiece deformation of radial force, thus is advantageous to the processing thin type of precision parts and increase the processing speed of thin-walled parts, and cutting force is small, the burden on the cutting tool and machine tool is small, so you can better protect double spindle car milling compound machine tool accuracy.

Advantages three, the workpiece speed is low

The workpiece speed is relatively low, in the processing of thin-walled parts will not cause deformation due to centrifugal force.

Advantage four, small thermal deformation

When using double spindle turning and milling compound, the whole cutting process has been adiabatic, so the tool and chip away a lot of heat, tension will lead to the temperature of the device is relatively low, not easy to occur thermal deformation.

Advantage five, one-time completion

Double spindle turning and milling composite mechanic machine tool can make all the tools to be processed in a clamping process to complete all the boring, turning, drilling, milling and other processes, so as to avoid the trouble of replacing the machine tool, can greatly shorten the workpiece production and processing cycle, avoid the problem because of repeated clamping.

Advantage six, reduce bending deformation

The use of double spindle turn-milling compound processing method can greatly reduce the bending deformation of parts, especially when processing some thin and long parts without middle support.