The laser is a beam of energy with optimum monochromatic properties, high brightness and great energy density, as well as good directionality. Lasers have unique characteristics and are therefore widely used in applications such as laser marking, laser spectroscopy, laser ranging, laser radar, laser cutting, laser weapons and many more, all of which have great potential for application and development. Laser processing technology has a very important place in the sheet metal processing process, greatly improving the labour productivity of the sheet metal process and promoting the development of the sheet metal process. In sheet metal processing, the use of laser cutting machines can greatly reduce the processing cycle, improve processing accuracy, speed up the development of products, but also reduce production costs, these advantages are many manufacturing companies concern, and gradually in the sheet metal processing using laser cutting machines.

What is the principle of laser cutting in the sheet metal processing process?

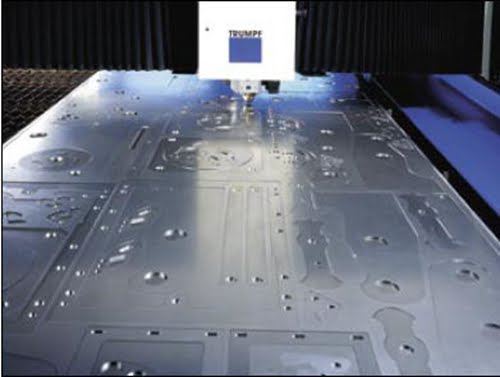

The principle of laser cutting is that the laser cutter focuses the laser on any point on the surface of the material to be processed, and the light energy of the laser is converted into heat energy at this point, within a very short period of time, the temperature of the laser irradiation point will rise rapidly to reach the melting point of the material, and then rise to its boiling point, and the material will begin to melt and then vaporise, after which this laser irradiation point will become a hole; at this time the laser cutter has The laser beam is controlled by the laser cutter and starts to move along the set path, during which the surface of the material to be cut will liquefy and vapourise, and the path through which the laser beam passes will leave a thin slit.

Laser cutting in thin sheet processing

Software advantages to enhance the utilisation of thin sheet materials

AMADA's laser cutting software is AM-LASER, which uses CADKEY 7.0 as its CAD workbench and is supported by Lnest and rotary support functions. It also effectively reduces the number of times the material is clamped. Bystronic's laser cutting machines use the more advanced principle of "flying light path", so that the sheet to be processed does not have to be clamped, there is no processing dead zone and the speed of processing is greatly increased; when preparing the cutting programme, the same thickness but different types of material must be arranged on top of the fixed-size material in accordance with the production plan. This enhances the utilisation of the material.

Reducing the number of abrasives and increasing the speed of product development

In recent years, there has been an increase in the proportion of less-cutting, non-cutting and sheet-metal parts in textile machinery products. However, the current market competition is very fierce, how to meet the relatively small but large number of varieties of users as soon as possible to exchange requirements, which is a great problem faced by every enterprise. If the process equipment is too outdated, then each sheet metal part can take a lot of time to produce in the drop production process. In addition, new products are produced in small batches in a single room, and the parts are changed and adjusted according to the trial situation, so that the use of moulds increases the cost considerably. The use of laser cutting, without the use of moulds, saves a lot of investment in moulds, shortens the production lead time and accelerates the speed of product development. In today's fast-changing market, the faster the product development, the faster the market can be occupied. Laser cutting of stamped parts also ensures the accuracy of the mould design. The drop is the first step in the stretch forming process and the drop dimensions are usually corrected. However, by using the laser cutting machine to cut out the stamping parts for trial processing on the forming die, the size of the drop die can be worked out more accurately, which is the basis for future mass production.