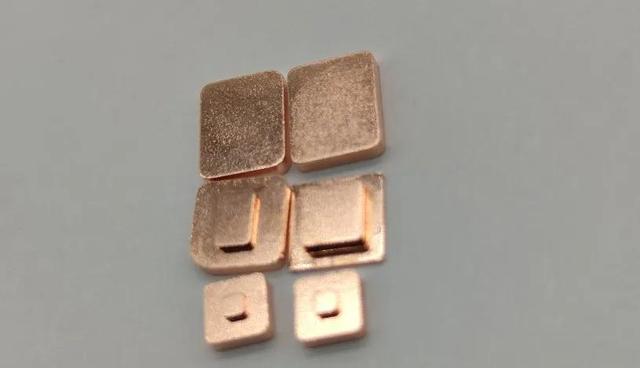

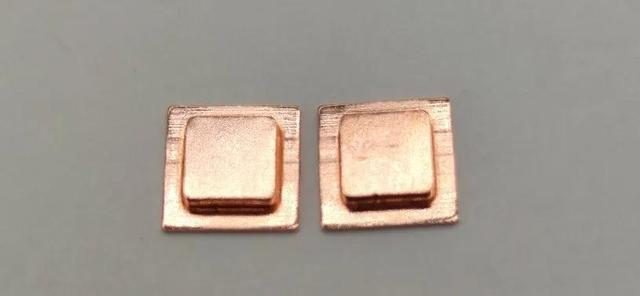

Precision hardware parts processing methods can be divided into CNC machine processing cold pier processing powder metallurgy processing continuous die cold extrusion processing precision stamping processing. Precision hardware parts processing using CNC machine processing advantage is the processing of high precision no mold costs, the disadvantage is the low efficiency is not suitable for a very large number of precision hardware parts processing; precision hardware parts using cold pier processing advantage is fast and save material, the disadvantage is not high precision, can only guarantee the precision tolerance plus or minus 10 silk, which is a lot of automated assembly of electronic factories can not accept the precision, in addition there will be 3000-10000 yuan or so of mold costs! The disadvantage is that there is a high temperature firing process after the powder metallurgy molding, which leads to deformation precision is not high, but also has a high mold fee; precision hardware parts using continuous die cold extrusion processing advantage is the speed of the fastest production of more than 350 per minute, high precision products can be controlled tolerance plus or minus 2mm, in addition to the product strength is very High can reach 2-3 times the strength of the product raw material, the disadvantage is that the mold fee is more expensive general starting price of about 3W, precision hardware parts using precision stamping processing method advantage is the production speed and high precision, the disadvantage is that the mold cost is high, can do precision structural parts of the process only stretching way. Dear friends, the advantages and disadvantages of several ways of processing precision hardware parts are clear, encounter different precision hardware parts or miniature hardware parts you can choose the most suitable and most economical way of processing according to the different requirements of customers! Here are some of the precision hardware parts processed by Steindl Hardware using the continuous die cold extrusion method, you can enjoy them and feel free to leave your comments!