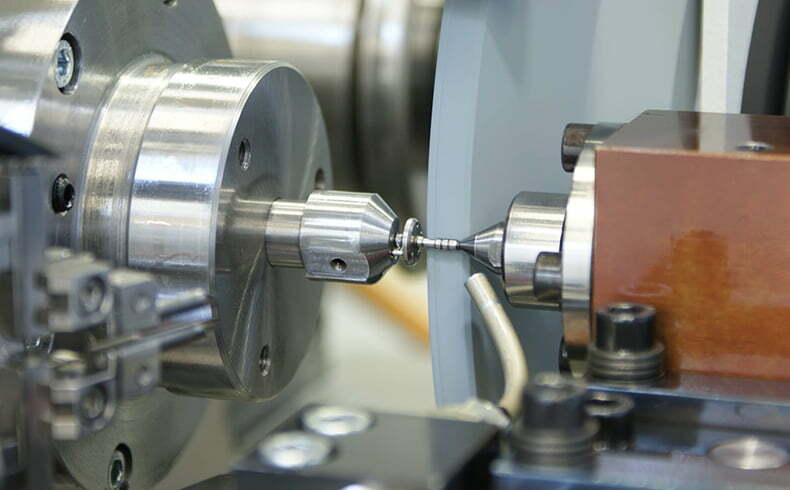

Turning and milling composite processing is the automation technology production and processing of strong high precision machining technology, refers to the workpiece of the entire production process is all under the manipulation of CNC machine tools, can produce and process some very different composite materials, nowadays the composite materials are commonly used in all aspects of life, especially aerospace, some ultra-high precision machinery manufacturing.

A, the type of CNC machining center composite material

Composite material according to its composition into metal materials and metal composites, non-metallic materials and metal composites, non-metallic and non-metallic composites. According to its structural characteristics and divided into.

1, chemical fiber composite material. A variety of chemical fibers to improve the body placed in the base material materials combined. Such as chemical fiber elastomer materials, chemical fiber to improve the alloy.

2, compartment composite material. By the characteristics of the different surface raw materials and core board composition. Usually the base material is hard and thin; the core material is light and low compressive strength, but with a certain strength and thinness. Divided into solid core skirt wall and honeycomb compartment two kinds.

3、Sand composite material. The hard sand joint distribution in the foundation, such as diffuse reinforced aluminum alloy, metal ceramics, etc.

4、Doped composite material. By two or more types of raising phase raw materials mixed in a base material phase raw materials. Compared with the ordinary single-phase composite material, its impact compressive strength, fatigue limit and impact toughness significantly improved, and has a unique thermal deformation characteristics. Divided into layer doping, solid layer doping, core hybrid, layer/solid layer doping and super hybrid composite materials.

Second, turning and milling composite processing production and processing of composite materials should pay attention to the problem

1, carbon fiber material composite material solid layer compressive strength is low, easy to appear under the effect of cutting speed hierarchy, and therefore perforation or cutting edge should reduce the axial force. Perforation provisions of high-speed rotation, small knife, CNC machining center speed ratio is generally in 3000 ~ 6000r/min, cutting speed to 0.01 ~ 0.04mm / r, twist drill with three tips two edges or two tips two edges way good, sharp tip can first cut off the carbon fiber material layer, two edges to the surface layer has a repair effect, set gold steel stone twist drill sharpness and wear resistance performance is outstanding. Composite material and titanium metal compartment perforation is a difficult point, generally choose the overall carbide drill, according to the main parameters of milling titanium metal cutting to carry out milling, from the titanium metal side first, until the drilling through, milling with lubricating fluid to reduce the composite material scalding. American Boeing Company specializes in the development of PCD composition twist drill for the perforation of compartments.

2, 3 types of new overall carbide tool composite material production and processing turning tools for drilling the actual effect is stronger, they are some of the same characteristics: high stiffness, small helix angle, or even 0 °, professionally developed herringbone edge, are able to reasonably reduce the CNC machining center radial cutting speed, reduce the hierarchy, its work is highly efficient and practical effect is very good.

3, composite material cutting for powder, health damage, should take a power vacuum cleaner vacuum, the choice of water-cooled cooling can also reasonably reduce the smoke and dust environmental pollution.

4, carbon fiber material composite material prefabricated components are generally larger specifications, look like a cumbersome structure, strength and hardness are very high, classified as difficult to produce and process raw materials. Drilling course cutting speed is relatively large, drilling heat is not easy to transmit, more serious time will burn paste epoxy resin or make resin soft, CNC blade damage is more serious, and thus the CNC blade is an important carbon fiber processing, its drilling principle is closer to the cutting is not cutting, therefore, turning and milling composite processing drilling angle speed is usually more than 500m / min, the choice of high-speed rotation of small walking tool countermeasures. Cutting edge production processing CNC inserts are generally used overall carbide tool extrusion tap turning tool, electroplating process gold steel stone granular material sand wheel piece, inlay gold steel stone turning tool, copper-based gold steel stone granular material woodworking saw blade.