CNC milling machines and machining centres in the end what is the difference, in fact, this problem is not only for the layman is very confused, many people in the industry also have a silly distinction.

Simply put, the machining centre is an upgraded version of the CNC milling machine, if the CNC milling machine is likened to a steel saint, then the machining centre is a golden saint of this level.

There are actually three main differences between the two types of machining equipment.

The biggest difference is whether it comes with a tool magazine or not

Ordinary CNC milling machines also have a CNC operating system (e.g. Japanese Fanuc, German Siemens, Chinese Huazhong or GuangDu, etc.) and also have three feed axes and a rotary spindle, their machining mode geometry is exactly the same, and they can also basically achieve the same machining capacity.

The biggest difference between them is whether the equipment comes with a tool magazine, the machining centre is in fact a CNC milling machine with a tool magazine, the machining centre can achieve a clamping and complete the work of multiple machining processes, such as milling, drilling, tapping and so on, because it can achieve automatic tool change, and in the process of continuous processing of multiple work processes, the operator is not required to intervene manually, as long as the preparation of a good The operator only has to prepare the program, configure the tools and the corresponding parameters. The CNC milling machine is not, CNC milling machine can also achieve a clamping processing multiple processes, the difference is that in the process of conversion, you must manually change the tool, so its processing process is not continuous, is a number of degrees of intermittent execution, such processing both in the processing quality, or processing efficiency, are slightly inferior to the machining centre.

So when you see a machine in the future, you can determine very straightforwardly whether it is a CNC milling machine or a machining centre by whether it has a tool magazine, which is a gold standard.

Whether it is fully guarded or not

In fact, this is not absolute for a lot of equipment, many CNC milling machines have gradually started to make full protection processing mode, of course, there are also many old CNC milling machines using still open processing method, or semi-protection processing method, which to a certain extent and the current machining centre is still a certain difference, of course, this difference is not absolute (again, statement).

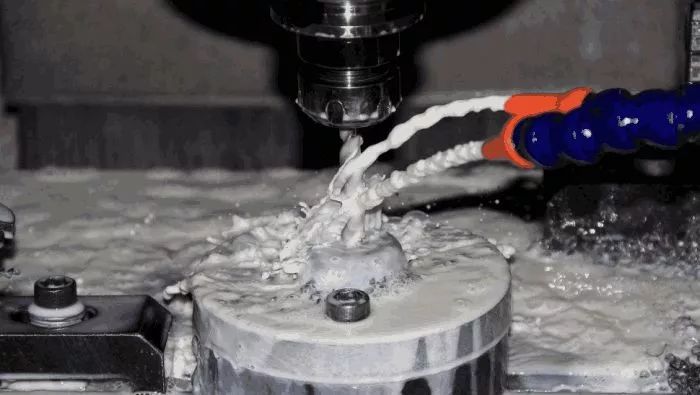

In fact, this and the development process of the equipment has a lot to do with the primary stage of CNC processing equipment, in fact, many manufacturers are not too focused on the appearance of the design and safety protection, basically still stay on the functional requirements, so many CNC milling machines are made into an open form, or do a good point is the semi-open form, this CNC milling machine, although there is not much defect in the function, but in Although this kind of CNC milling machine is not too defective in terms of function, there is still a big deficiency in the safety of processing and processing environment, for example, the processing of high-temperature iron chips will be splashed onto the human body, causing harm to the human body, and the coolant used to cool the tool during processing will also be splashed onto the operator, soiling the operator's clothes, etc. Therefore, although the progress of research and development of production equipment, especially the invasion of foreign high-end equipment, the design and manufacture of processing equipment in China is also And then towards a more humane, more beautiful, more artistic road in stride.

This is a process, any progress needs a process, product technology, product art, is the future unified requirements for industrial products, but also the future development of industrial products must be the road.

With or without automatic chip conveyor

This criterion is the same as the previous one, it is not an absolute criterion, it is also a motorized criterion based on the development process of the processing equipment, the reason for this is also because the previous equipment in the research and development of some hindsight on the function of the trade-offs caused by many new CNC milling machines, full protection and automatic chip conveyor are basically standard, there is no big difference with the machining centre.

But for those old CNC milling machines, this criterion still works, after all, a device that does not even have good protection, is in any case not dare to ask for any automatic chip removal, in fact, now the practitioners of the machinery industry, should thank this era, is this era provides the technology and ability to free our hands, so that we can more easily and efficiently engaged in our own work, and with the With the full development of Industry 4.0, this liberation of the workforce is also accelerating at a frantic pace, and will even produce the elimination of many workforces or labour methods, for which we must always be prepared.

In conclusion

For the above reasons, so if you want to choose a machine, of course it is better to choose a machining centre, at least in terms of processing efficiency to be much higher, processing range is also much larger, especially with the use of the fourth axis of the rotary table, it is simply a magic tool ah.

If you want to learn a machining machine, you should also learn the operation of the machining centre, at least in the programming to be more complex, in the design of the fixture and the preparation of the machining process should also be more complex, after all, do composite machining, is very need to test the technology and ability, of course, this is also a guarantee of the quality of processing.