CNC machining has evolved into one of the most critical manufacturing processes used on shop floors around the world.

Adding computer control to a previously manual process has resulted in leaps and bounds in the accuracy and precision of machined parts.

The evolution of CNC machining technology has given rise to various forms and variations of the technology. These include 3-axis and 5-axis CNC machines.

We'll start today with 3-axis CNC machining

What is 3-axis CNC machining?

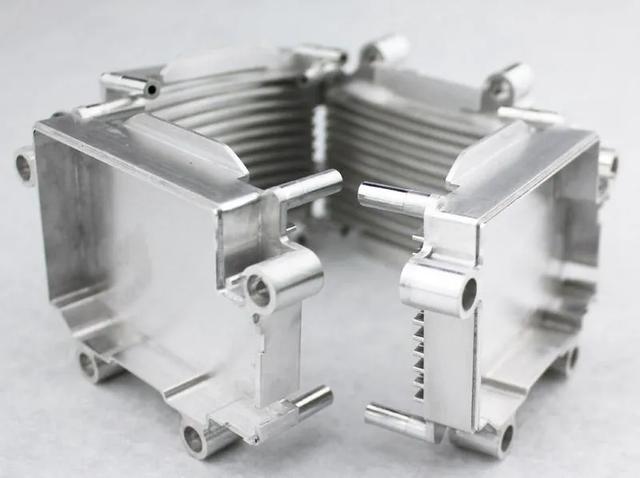

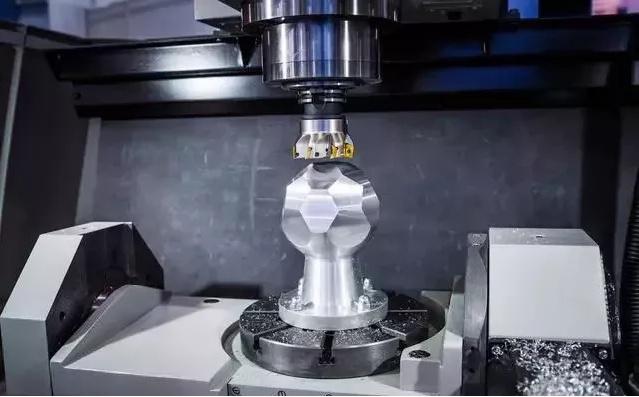

3-axis CNC machining is the simplest and most common form of machining. This process uses a rotating tool that moves along 3 axes to machine a fixed workpiece.

The cutting tool moves along the X, Y and Z axes to trim excess material from the part. In addition, it can even move along these multiple axes simultaneously to create the desired design.

This means the CNC machine can cut into the part from side to side, front to back, up and down. However, the table that holds the workpiece in place is not free to move at all.

The benefits of 3-axis machining

Although there are more advanced systems available in the industry today, 3-axis CNC machining is still widely used. So, let's look at some of the advantages of keeping it.

Low Cost

3-axis CNC machining is best suited for the rapid production of basic geometries and simple parts. In addition, it is relatively easy to program and set up the computer for production runs in 3-axis machining.

Versatility

3-axis CNC machining is a highly versatile part manufacturing process. A variety of operations such as drilling, milling and even turning can be performed by simply changing tools.

These machines also have an integrated automatic tool changer, which extends their capabilities.

Disadvantages

3-axis machining is also hampered by a variety of factors that prevent it from meeting all machining needs. Some of these factors include.

Design limitations.With 3-axis CNC machining, you are limited to basic shapes and geometries, for example, it is not possible to create undercut features. Although the machine can do more in the hands of a skilled machinist, it still cannot match the complex shapes obtainable with 4- and 5-axis CNC machines.

In addition, it is not suitable for machining parts with special deep features or narrow cavities.

Multiple setups

Since the table holding the workpiece is stationary, the machinist must change its orientation several times in order to machine its other faces.

This reorientation results in a loss of accuracy, not to mention the time wasted in doing so.

Poor surface finish

The surface finish obtained from 3-axis machining is relatively poor, especially on Z-cuts. This happens because the tool is longer. As a result, it experiences more vibration, which can ruin the finish of the product.