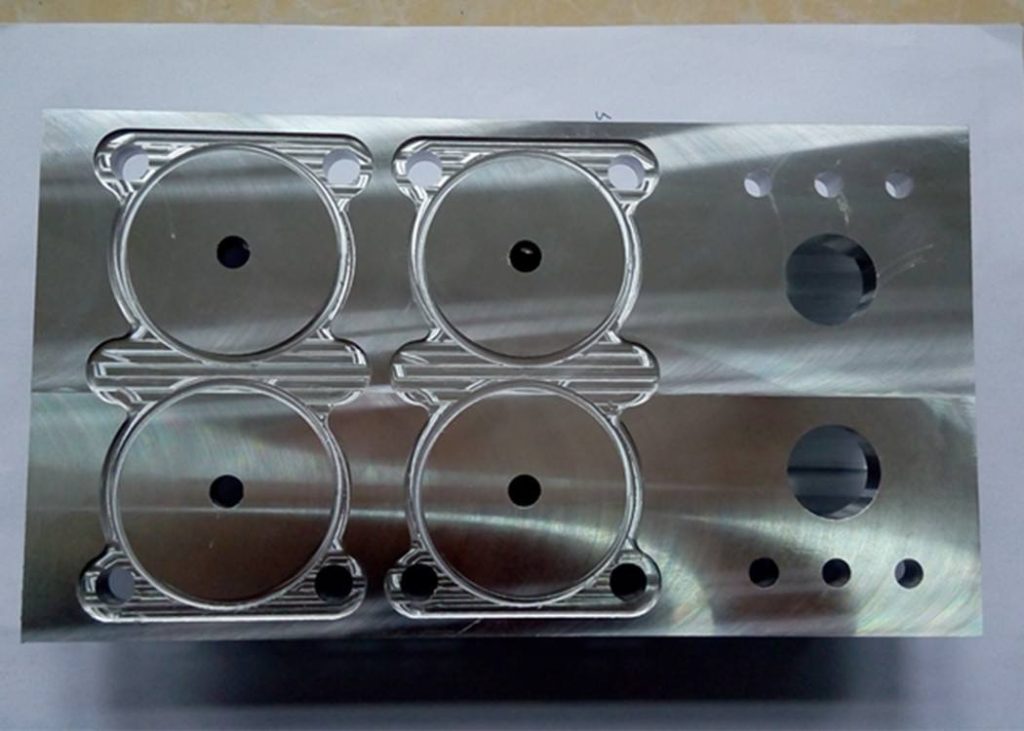

When milling parts, the workpiece is fixed and positioned with milling machine accessories. Common milling machine accessories include.

Flat tongs are a general fixture. When using, first correct the position of the flat jaw pliers on the workbench, and then clamp the workpiece. It is generally used for small and regular parts, such as square plate parts, disc and sleeve parts, shaft parts and small supports.

When installing workpieces with flat tongs, it should be noted that the machined surface of workpieces should be higher than the jaw, otherwise the workpieces should be padded with sizing blocks; The clearance between the workpiece and the sizing block shall be prevented; To protect the machined surface of the workpiece, a soft metal sheet can be placed between the jaw and the workpiece.

The pressing plate is to place the workpiece directly on the workbench, press and fix it with the pressing plate. Some large workpieces can be fixed by pressing plates.

Dividing head dividing head is an important accessory of milling machine.

Function of dividing head

1) Divide the workpiece around its axis (equal or unequal). Such as hexagon, gear, spline, etc.

2) Turn the axis of the workpiece to the required angle (horizontal, vertical or inclined) with respect to the table top of the milling machine. Therefore, slopes with different angles can be processed.

3) When milling spiral grooves or cams, it can coordinate with the movement of the workbench to make the workpiece rotate continuously.

Structure of indexing head

The base of the indexing head is equipped with a rotary body, and the spindle of the indexing head can rotate within 90 ° upward and 10 ° downward in the vertical plane with the rotary body. The front end of the spindle is often equipped with a three jaw chuck or.

When indexing, pull out the positioning pin and turn the handle. The worm is driven to rotate by the spur gear pair with a tooth ratio of 1 / 1, and the main shaft is driven to rotate and index by the worm wheel and worm pair with a tooth ratio of 1:40. See the physical object or wall chart for details. When the handle of the indexing head rotates for one rotation, the worm gear can only drive the main shaft to rotate by 1 / 40. At this time, the number of revolutions n that the indexing handle needs to turn is.

(3) Graduation method

Only a simple dividing method is introduced here. For example, the graduation z = 35. The number of rotations of the handle during each indexing is:

That is to say, the handle needs to be rotated for one rotation every time it is indexed. This rotation is controlled by the indexing disk. Generally, the indexing head is equipped with two indexing disks. There are many circles of holes on both sides of the dividing plate, and the number of holes in each circle is not equal, but the hole spacing on the same hole circle is equal.

In order to avoid the cumbersome counting of holes each time and ensure the reliable number of holes that the handle turns, the included angle between the two fractal clips on the indexing plate can be adjusted to be equal to the number of holes to be divided, so that the indexing can be accurate in turn.

- The rotary table is mainly used for the indexing work of large parts or the machining of non-circular arc surfaces. There is a pair of worm gears and worms inside, and the handwheel is coaxially connected with the worm. Turn the hand wheel to rotate the turntable through worm gear transmission. There are scales around the turntable to observe and determine the position of the turntable; The dial on the hand wheel can read the accurate position of the turntable.