Five axis machining, CNC machine tool machining a mode.

According to ISO, when describing the movement of CNC machine tools, the right - handed rectangular coordinate system is used; The axis parallel to the main axis is defined as the z axis, and the rotation coordinates around the x, y and z axis are A, B and C respectively.

The motion of each coordinate axis can be realized by the table or by the motion of the tool, but the direction is defined by the motion of the tool relative to the workpiece.

Usually five-axis linkage refers to the linear interpolation motion of any 5 coordinates in x, y, z, A, B and C.

In other words, the five axes are the x, y, and z axes of movement plus any two axes of rotation.

Compared with the common three-axis machining, five-axis machining refers to the processing of geometrically complex parts, the need for machining tools to be able to position and connect in five degrees of freedom.

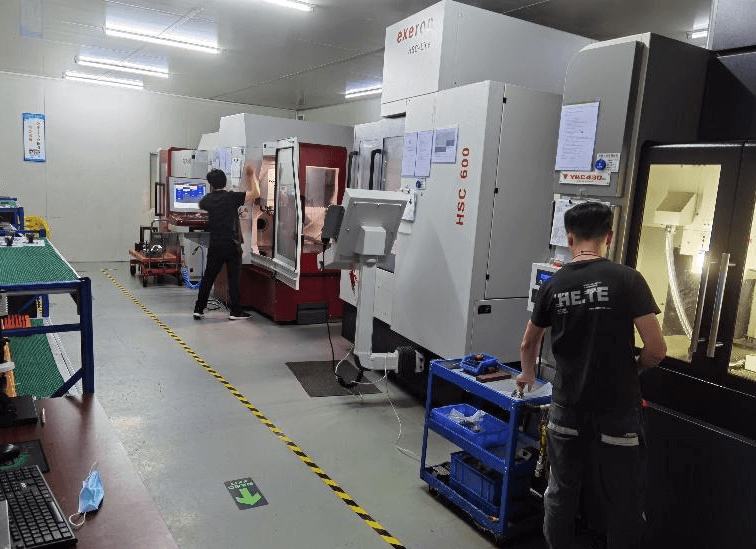

The machine tool used in five-axis machining is usually called five-axis machine tool or five-axis machining center. Five-axis machining is often used in the aerospace field to process body parts, turbine parts and impellers with free-form surfaces.

Five-axis machine tool can process the different sides of the workpiece without changing the position of the workpiece on the machine tool, which can greatly improve the processing efficiency of prismatic parts.

5-axis machining is the use of computer numerical control (CNC) to move a tool or part along five axes simultaneously. The cutting tool moves continuously along each axis so that the tip is always perpendicular to the part. This process allows you to make all sorts of complex parts.

Why choose 5-axis CNC machining

5-AXIS CNC Machining

Easily process special-shaped mechanical parts without multiple setups, reducing errors, shortening production time, and improving yield and product quality.Tolerance: ±0.001mm

5 Axis vs. 3D printing: The core difference between the two is that 5 Axis is a subtraction process while 3D printing is an additive process.

The two manufacturing methods are at their best when they work in harmony and complement each other. You can't really use one procedure in place of another. If you have complex parts, a variety of materials, and a lot of work, then 5 axis will be your best choice. However, you can use 3D printing to design certain parts.

5 axis vs. 3+2 axis: It seems difficult to tell the difference between 3+2 axis machining and 5 axis machining. 3+2 axis machining, often called 5-axis indexing machining, requires stop and start, whereas 5-axis machining is continuous. 5-axis machining is an easier and faster way to achieve the same or better results.

Achieve the impossible

When you use 5-axis machining, you can make parts that would otherwise seem impossible. This process allows you to mill, drill, and tap multiple complex shapes in a single setting. Create any combination of complex shapes with a single setting.