The original CNC equipment can program two axes (meshing) and three axes (milling), but with the development of control, servo and tool technology, we can now complete 4-axis and 5-axis linkage machining. With a 5-axis machine tool, you have only 2 motion axes compared to a 3-axis machine tool. This advanced processing technology enables manufacturers to produce more complex or more complex parts with faster speed and higher quality without additional processing.

What is five axis NC machining?

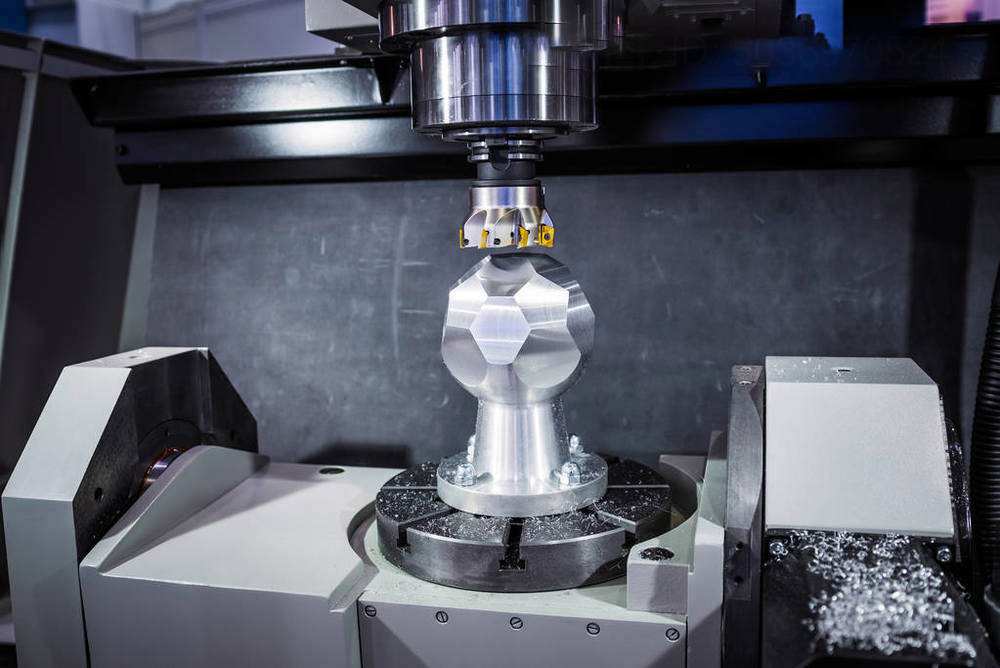

Five axis refers to the three moving axes of x, y and z plus any two rotating axes. Compared with the common three-axis machining (x, y, z three degrees of freedom), five axis machining refers to machining more complex geometric parts, and machining tools need to be positioned and connected on five degrees of freedom. They use several different axis configurations to perform machining operations. (CNC machining: 3-axis VS 4-axis VS 5-axis)

Current types of five axis CNC machine tools

In the mechanical design of a five axis machining center, machine tool manufacturers have been working tirelessly to develop new motion modes to meet various requirements. To sum up, there are many kinds of five axis machine tools on the market. Although their mechanical structures are various, they mainly have the following five types:

Two rotation coordinates directly control the cutter axis direction (double swing head form)

Two coordinate axes are at the top of the tool, but the rotation axis is not perpendicular to the linear axis (pitch type swing head type)

Two rotation coordinates directly control the rotation of space (double turntable form)

The two coordinate axes are on the workbench, but the rotation axis is not perpendicular to the linear axis (pitch workbench)

Two rotation coordinates, one on the tool and one on the workpiece (one swing and one rotation)

5-axis machining is considered to improve efficiency and reduce the time required. The 5-axis provides flexibility and avoids possible collisions with the tool rest. The name of the tool to be cut is in the right position, which also provides the right posture for cutting. The configuration of the 5 axis machining defines the axis to be used. The requirements of the shaft depend on the machine and tools to be cut, depending entirely on whether the parts are single or multiple.

Advantages of Five Axis NC Machining

Fewer settings

The first and most important point is the ability to process complex shapes in a single setup. For contour parts or multi-faceted machining, the 3-axis machine tool needs to be set many times, which may lead to incorrect alignment, high cost and other errors. The five axis machine tool can process almost all visible surfaces except the bottom or clamping area. This function greatly reduces the need for multiple settings or special lamps. In some cases, it reduces the number of settings to one. This improves efficiency, saves time, reduces costs, and prevents operator errors.

Five axis machining has obvious advantages, including saving time and money, which goes without saying. Five axis CNC is the most difficult and widely used CNC technology. It integrates computer control, high-performance servo drive and precision machining technology, and is used for efficient precision automatic machining of complex surfaces. Although five axis CNC machine tools are expensive, they are now the main products of forward-looking machine tool factories.