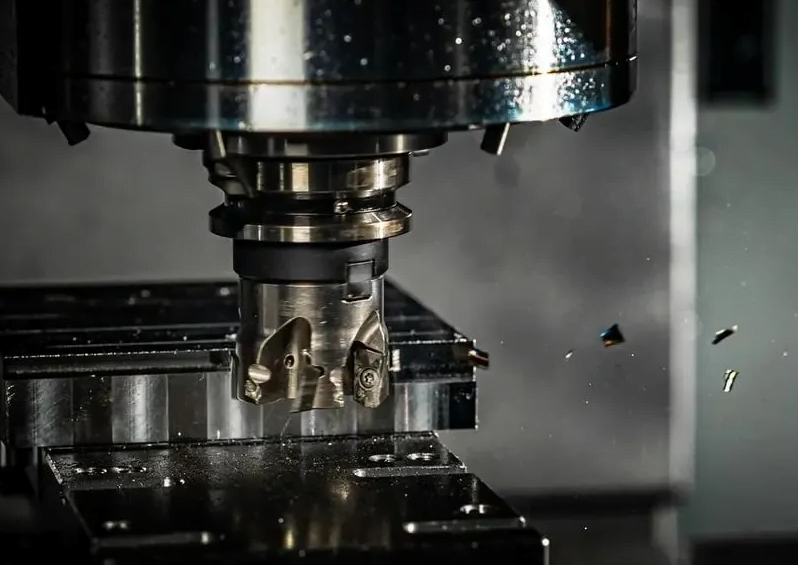

What is precision parts machining?

It belongs to one type of mechanical processing, but it is very precise and has relatively high requirements for production equipment and processing processes.

With the development of industrial automation, there are more and more classifications of precision machining , the direction is becoming more and more refined and more specialized; the future precision machinery

will become more and more integrated, it is no longer the simple machining of the past, and its combination with high technology can just play its role better, In particular, the digitalization of processing has brought about a qualitative leap in its development, and it will serve as a key science for the development of the industry in the future;

Machining workshop

Mechanical equipment is made up of many precision parts. Each part plays its own role, and these parts are required to be assembled. After different parts are processed, we can get more suitable parts, so in order to make these products better for the equipment, many people can't do without the important part of precision machining.

In order to ensure the machining accuracy of precision parts, it is recommended to separate rough machining and finishing machining.

This is because in the rough machining of the cutting volume is relatively large, the parts will be subject to cutting force, clamping force is relatively large, at the same time, the heat generated is also relatively large, which will lead to the machining of mechanical parts will have obvious machining hardening of the surface, and the internal stress of the parts will be relatively large.

If continuous roughing and finishing, due to the redistribution of stress, the precision of the finished part will be reduced.

CNC lathe workshop

In the process line of precision parts processing, a heat treatment process is often arranged. The location of the heat treatment process is arranged to improve the cutting performance of the metal, such as annealing, normalizing and quenching and tempering. It is generally arranged before machining. The machining process of precision parts is very strict. The feeding and retracting are interlocked, and the precision of the size can be grasped, which can reduce the loss of materials and reduce the cost. If the size of the part is wrong, it will become a waste product, and the part can no longer be used. used;