Stamping is a production technology that, with the power of conventional or specialized stamping equipment, deforms the sheet directly in the die to obtain a product part of a certain shape, size and performance.

The sheet, the die and the equipment are the three elements of stamping. Stamping is a cold deformation method of metal processing. Therefore, it is called cold stamping or sheet metal stamping, or stamping for short.

It is one of the main methods of metal plasticity processing, and also belongs to the material forming engineering technology.

In order to meet the requirements of shape, size, precision, batch size and raw material performance of stamped parts, a variety of stamping processing methods are used in production. In summary, stamping can be divided into two categories: separation process and forming process.

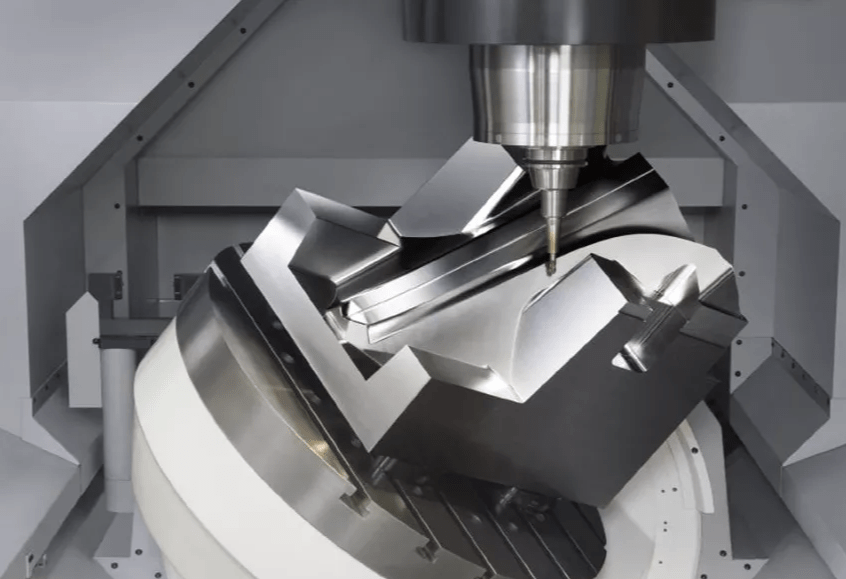

The die used for stamping is called a stamping die, or punching die for short.

The die is a special tool to process the material in bulk into the required stamped parts. Without a die that meets the requirements, it is difficult to carry out batch stamping production; without an advanced die, the advanced stamping process cannot be realized.

Design principles

(1) The designed stamping parts must meet the use and technical performance of the product and can be easily assembled and repaired.

(2) The designed stamping parts must be conducive to improving the utilization rate of metal materials, reducing the varieties and specifications of materials, and lowering the consumption of materials as much as possible. Low-priced materials should be used as far as possible to make the parts waste-free and scrap-free.

(3) The designed stamping parts must be simple in shape and reasonable in structure, so as to help simplify the die structure and the number of processes, i.e. to complete the processing of the whole part with the least and simplest stamping process and reduce the processing by other methods, and to facilitate the stamping operation and the organization of mechanized and automatic production, so as to improve the labor productivity.

(4) The designed stamping parts should be designed to have low dimensional accuracy and surface roughness level as far as possible to ensure normal use, and to facilitate product interchangeability, reduce scrap and ensure stable product quality.

(5) The stamping parts should be designed in such a way that they can be processed with the existing equipment, process equipment and process flow as much as possible, and that they are conducive to the extension of die life.

Advantages Editor.