The difference between ceramic CNC and ordinary CNC is that ceramic CNC has unique advantages in the processing of ceramics.

Ceramics because of its characteristics, will be harder than other materials, processing ceramics if careless operation, it is easy to damage the tool and the workpiece, high hardness, the machine tool needs to be more rigid.

Although ordinary CNC can also process ceramics, but the damage to the machine will be great, and in some ceramic products with relatively large grinding amount, it seems a little powerless.

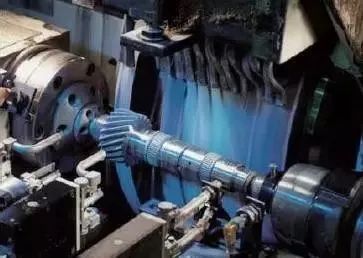

"Belt Ceramic Processing"

Ceramic materials are generally hard and wear-resistant, so processing ceramics not only needs to use the right tool, but also needs the machine tool itself to be able to take up the ceramic processing.

1.Machine tools can be used for a long time to process hard materials without any problems.

2.The protective effect of the machine tool is better, which can resist the ceramic powder from entering the machine tool.

As a result, ordinary CNC can process ceramic materials, but the configuration of ordinary CNC does not allow long processing of ceramic materials.

First of all, the rigidity of ordinary CNC is enough to process metal and other materials, and it can also process ceramic materials for a short time, but it is not enough to process ceramics for a long time, otherwise it may lead to skipping cutting.

Secondly, the ceramic powder is easy to enter the machine tool and cause damage to the lead screw guide rail.

Ceramic CNC is specially developed for the processing of ceramic materials out of a model, which strengthens the overall rigidity on the basis of ordinary CNC.

It can make the machine tool process ceramics for a long time without any problems. Multiple protection is installed on the lead screw guide rail to completely eliminate the worry of ceramic powder.