In the process of precision parts processing CNC machine tools in the cutting process inevitably exist tool wear problems, such as drill length shortened, milling radius smaller, etc., when the size of the processed workpiece also changes. If the system function has a tool size compensation function, you can enter the corresponding correction value on the operation panel, so that the size of the processed workpiece is still composite drawing requirements, otherwise you have to re-write the CNC machining program.

With the tool size compensation function, so that CNC programming is greatly simplified, in programming can be completely disregarded tool center trajectory calculation, directly according to the part contour programming. Before starting the machine tool processing, just enter the parameters of the tool used, the CNC system will automatically calculate the coordinates of the tool center trajectory, reducing the labor intensity for the programmer. In addition, when the size of the workpiece does not match the drawing requirements during test cutting and machining, the appropriate part can be machined with the help of the corresponding compensation.

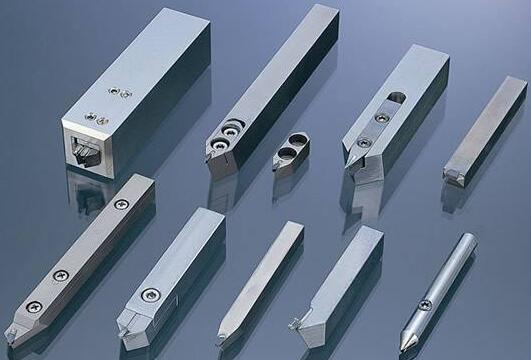

There are usually three types of tool size compensation in precision part machining: tool position compensation, tool length size compensation, and tool radius size compensation. There are two types of tool compensation used on CNC milling machines.