China machining shop refers to the whole process of making products from raw materials. For machine production, it includes transportation and storage of raw materials, preparation for production, manufacturing of blanks, processing and heat treatment of parts, assembly and commissioning of products, painting and packaging, etc.

The content of production process is very extensive. Modern enterprises use the principles and methods of system engineering to organize production and guide production, and regard the production process as a production system with input and output.

In the production process, the process of changing the shape, size, location and nature of the production object to make it a finished or semi-finished product is called a process. It is an important part of the production process.

How many categories can the process of China machining shop be divided into?

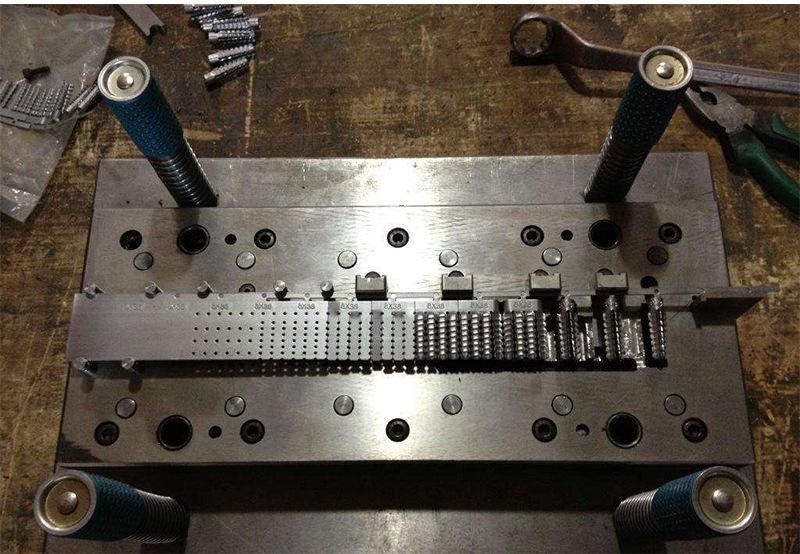

The technological process can also be divided into casting, forging, stamping, welding, machining, assembly and other technological processes. The mechanical manufacturing technological process generally refers to the sum of the machining technological process of parts and the assembly technological process of machines. Other processes are called auxiliary processes, such as transportation, storage, power supply, equipment maintenance, etc. The technological process is composed of one or several sequential processes, and one process is composed of several work steps.

Working procedure is the basic unit of machining process. The so-called process refers to the part of the process that a worker continuously completes for the same workpiece on a machine tool. The main feature of forming a process is that the processing object, equipment and operator are not changed, and the content of the process is completed continuously.

A step is a step that is completed by a machining tool on the machining surface at one time, under the condition that the machining surface, the machining tool and the cutting parameters remain unchanged.

To formulate the machining process, it is necessary to determine how many processes the workpiece will go through and the sequence of the processes. A brief process that only lists the names of the main processes and their processing sequences is called the process route.

The preparation of the process route is to formulate the overall layout of the process. The main task is to select the processing method of each surface, determine the processing sequence of each surface, and determine the number of processes in the entire process. The process route must follow certain principles production type.

Production types are generally divided into three categories:

1. Single piece production: single production of products with different structures and sizes, and rarely repeated.

2. Mass production: the same products are manufactured in batches throughout the year, and the manufacturing process has certain repeatability.

3. Mass production: The number of products manufactured is very large, and most workplaces often repeat the processing of a certain process of a certain part process procedure design.

Design principles:

(1)The process procedures designed shall be able to ensure the processing quality of machine parts and meet various technical requirements specified by China machining shop

(2) The production rate of the process should be high, so that the products can be put on the market as soon as possible.

(3) Try to reduce manufacturing costs

(4) Pay attention to reducing the labor intensity of workers and ensuring production safety.